Engine Construction

Engine casings are constructed of die-cast aluminum alloy. All casings are sandblasted and subjected to chemical treatment that retards environmental oxidation.

Shafts are made of C45 steel according to unified standards. For particular applications it is possible to supply them in steel with different mechanical characteristics and according to the customer's drawing.

The bearings we use are made by leading companies in the industry and are manufactured specifically for electric motors, are prelubricated with lithium grease and axially preloaded through compensation rings in hardened steel. On request we can supply bearings lubricated with special grease for high temperatures.

General conditions

The electric motor is a component that can give rise to risks of mainly electrical origin. If used inappropriately, it can cause damage to people, animals and property. Here are some practical tips for the competent personnel responsible for installing and operating the motor

Installation

- Check that the motor has not been damaged during transport; remove any fasteners or guards used during transport; check that the shaft rotates freely.

- Carefully check the correspondence between the rated characteristics shown on the plate and the characteristics of the application for which the motor is intended.

- Pay attention to direct couplings and couplings with pulleys; excessive force can irreparably damage the motor bearings. In case of belt couplings, to avoid damages and/or vibrations, a perfect parallelism between the axis of the motor and the pulley must be guaranteed.

- When mounting the motor with feet (form B3), the same must be fixed to a solid and perfectly flat surface. In fact, any deformation suffered by the feet when tightening the fixing screws may cause them to break.

- In the case of motors with B14 flange and through pins, the length of the fixing screws must be determined in advance in order to avoid damage to the winding.

Commissioning

- To prevent unwanted voltage drops, make sure that the power cables are suitable in terms of capacity and insulation for the starting and full load currents.

- To protect the motor from overloads and short circuits, it is advisable to use appropriate protection circuits. In this regard, the use of fuses alone is not recommended.

- Make all grounding connections in compliance with current regulations.

- Before coupling, make sure that the direction of rotation of the motor corresponds to that of the application.

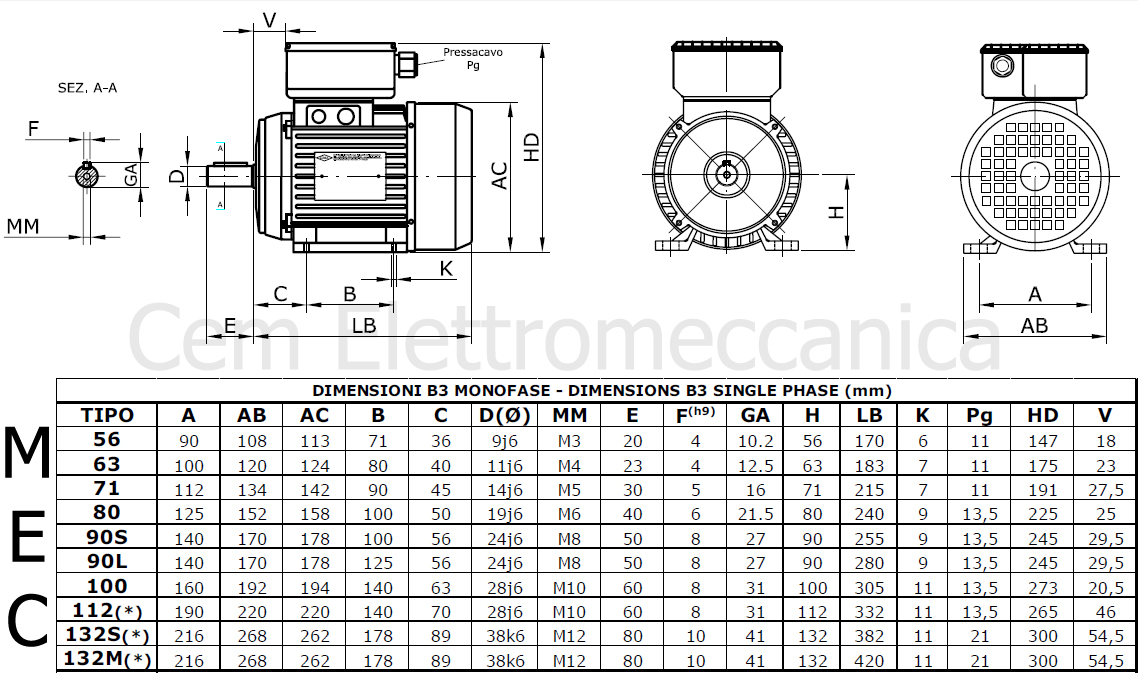

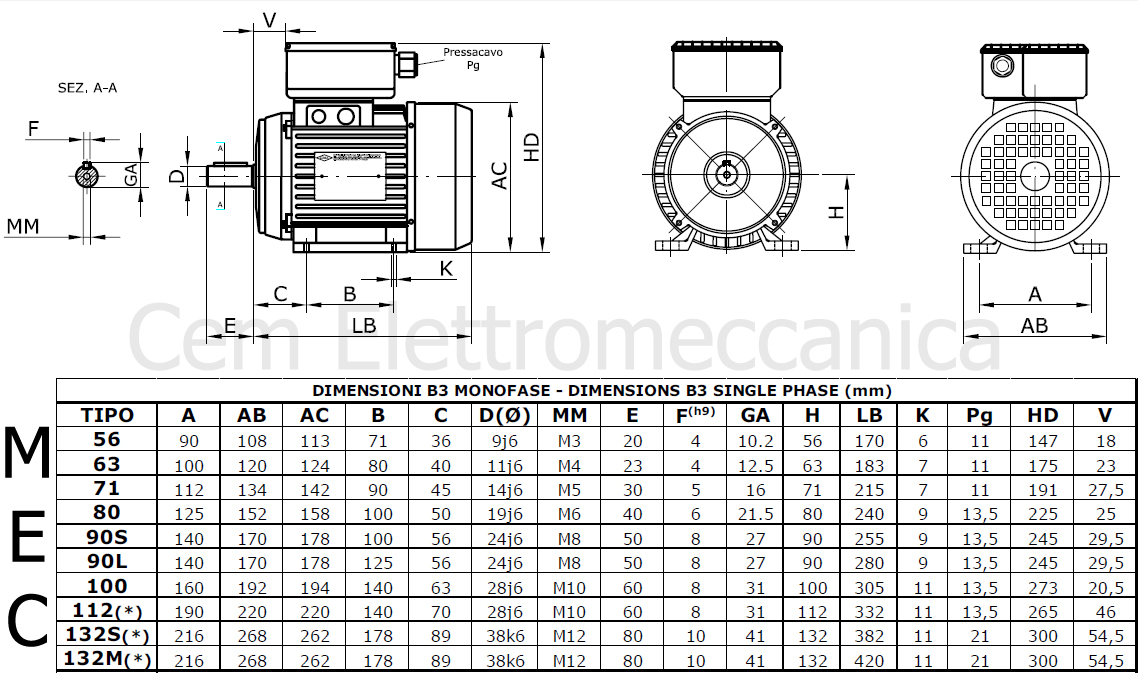

Standard sizes of single-phase motors B3